Automotive

In the automotive industry, maintaining vehicle quality and safety requires effective tracking and traceability of thousands of components from numerous suppliers. Direct part marking is essential for this purpose, and Beamer Laser Marking Systems, an all-American manufacturer, provides the necessary expertise.

Laser marking in the automotive industry.

Meet OEM Traceability Standards

For automotive suppliers, aligning with OEM traceability standards and systems, and collaborating closely with automotive manufacturers, represents an opportunity to enhance efficiency and address, or even preempt, safety-related concerns. Such efforts not only strengthen their partnerships with OEMs but also enhance their own business prospects. Leveraging laser technology for direct part marking emerges as a valuable tool in achieving these objectives.

ISO

9001

IATF

16949

SAE

AS9100

AIAG Standards

TRACE

Create Permanent, Legible Marks

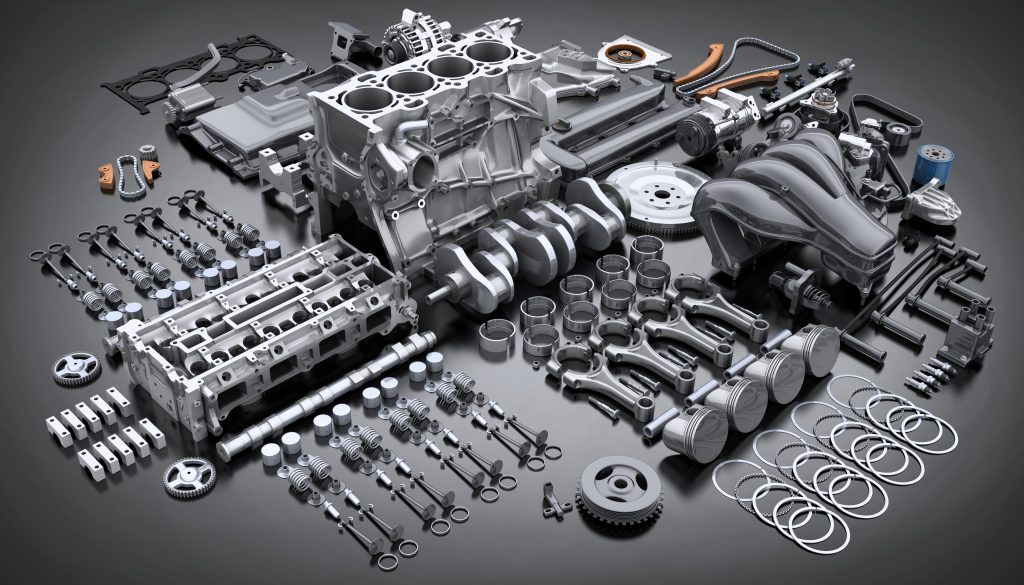

Laser marking technology is extensively used in automobile production to mark parts, thereby enhancing OEM traceability standards. This method ensures that a wide range of components, from complete assemblies to individual parts such as electronic components and windshield wipers, can be accurately traced throughout the supply chain. By aligning with these traceability standards, automotive suppliers can significantly improve efficiency, proactively address safety concerns, and strengthen their relationships with OEMs.

Serial Numbers

Part Numbers

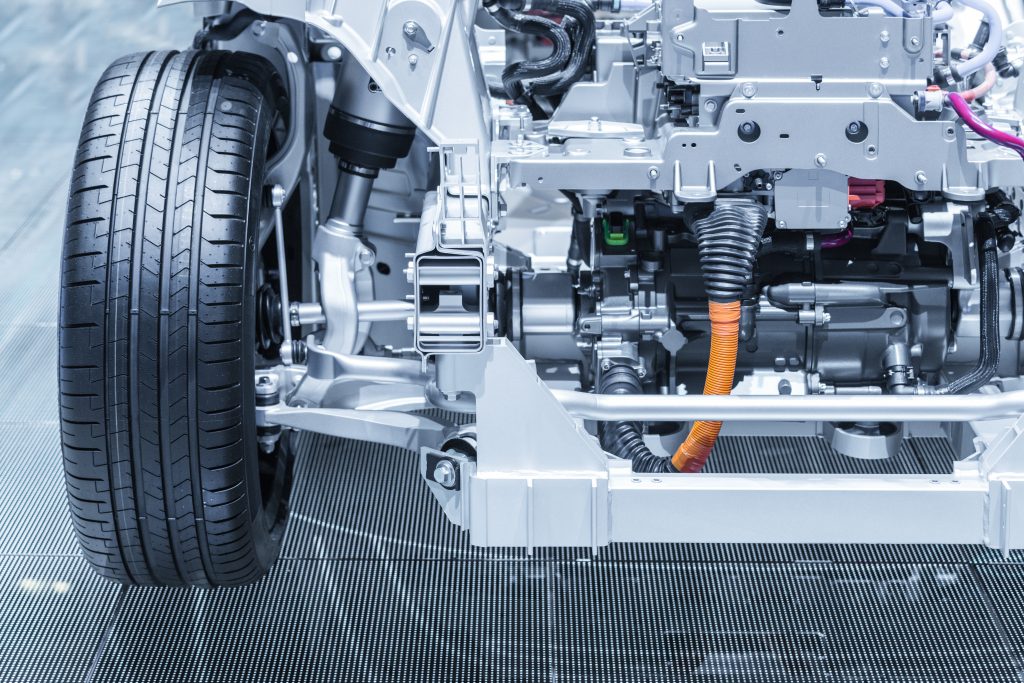

Eliminate Costs & Streamline Processes on Many Materials

Implementing laser marking systems in the automotive industry significantly reduces costs and streamlines production processes. By providing permanent, high-precision marks, laser technology eliminates the need for additional labeling or manual marking, which can be time-consuming and error-prone. This automation of the marking process leads to faster production times and minimizes the risk of misidentification, which can result in costly rework or recalls. Additionally, laser marking’s durability ensures that marks remain legible throughout the part’s lifespan, reducing the need for re-marking or replacements. This efficiency in marking not only decreases operational costs but also enhances overall production workflow, allowing manufacturers to maintain high standards of quality and safety while meeting tight production schedules.

REDUCE COSTS

No associated consumable costs

SUBSTRATES

Mark metals, composites & exotics

Industrial Grade Solutions

Beamer Laser Marking Systems provides aerospace manufacturers with marking solutions that increase productivity, efficiency, and meet or exceed regulatory requirements. And with an unmatched 100,000+ hour lifespan, our American-made, industrial grade fiber lasers provide consistent performance over extended periods of use, and reduced downtime and maintenance costs.

100,000+

Hour Lifespan Reduces Downtime and Maintenance Cost

CONSTRUCTION

1″ Steel Tube Frame and Powder Coated Steel Panels