Tool & Die

At Beamer Laser Marking Systems, we bring decades of expertise in laser marking technology, tailored specifically for the cutting tool, mold, check fixture, and die industries. Our laser marking and engraving solutions are designed to meet the precise demands of these sectors, providing a reliable method to brand, serialize, and create permanent, legible, and accurate markings and deep engravings.

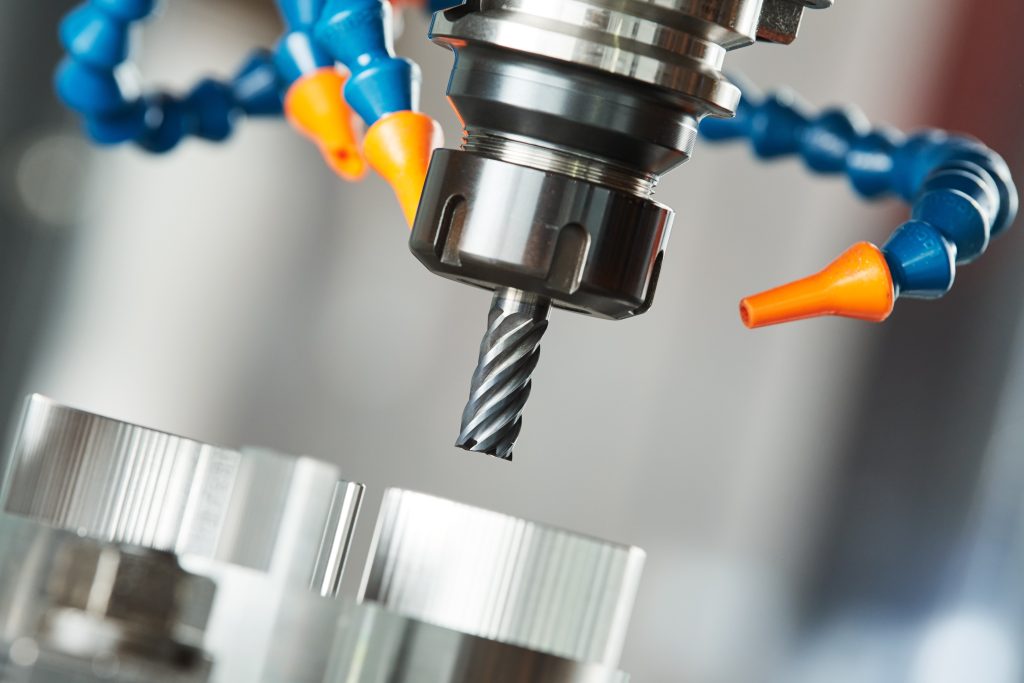

Laser marking in the tool & die industry.

Part Traceability

While other marking methods generate significant heat, laser marking uses a focused beam of light. This minimizes heat distortion, protecting the integrity of your precision-machined tools and dies.

Create Permanent, Legible Marks

Unlike methods like chemical etching or stamping, laser marking creates crisp, high-definition marks that won’t degrade over time. Even intricate details like logos, complex part numbers, and 2D data matrix codes are reproduced perfectly, ensuring readability throughout the entire life of your tool or die.

Our laser marking systems are suitable for a wide range of metals commonly used in tool and die making. Beyond simple marking, our systems offer additional functionalities like annealing for localized heat treatment and improved surface properties.

Logos

Serial Numbers

Part Numbers

Customer Numbers

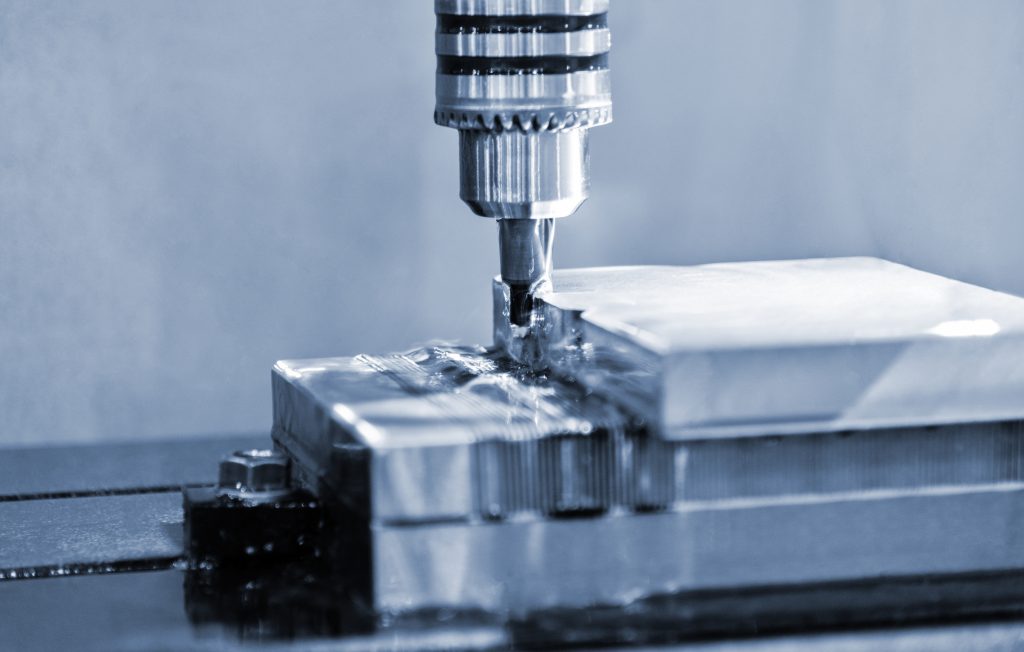

Eliminate Costs & Streamline Processes on Many Materials

Numerous case studies have demonstrated the impact Beamer Laser Marking Systems has had on the tool and die production process. Our solutions have consistently helped manufacturers achieve:

• Reduced production time through faster, more efficient marking processes

• Increased profitability by minimizing labor costs and eliminating wasted materials

• Improved quality control with permanent, clear, and error-free markings

REDUCE COSTS

No associated consumable costs

SUBSTRATES

Mark metals, composites & exotics

Industrial Grade Solutions

Beamer Laser Marking Systems provides aerospace manufacturers with marking solutions that increase productivity, efficiency, and meet or exceed regulatory requirements. And with an unmatched 100,000+ hour lifespan, our American-made, industrial grade fiber lasers provide consistent performance over extended periods of use, and reduced downtime and maintenance costs.

100,000+

Hour Lifespan Reduces Downtime and Maintenance Cost

CONSTRUCTION

1″ Steel Tube Frame and Powder Coated Steel Panels