Engineered Solutions

CUSTOM BUILT

For Your Operation

INTEGRATED

Into Your Workflow

POWERFUL

Precise Lasers

Let’s build something together.

If your application requirements fall outside of the capabilities of our standard machines, Beamer Laser Marking Systems will collaborate with your staff to engineer a custom solution for your specific marking needs. And with a programmable PLC and endless automation and technology bolt-ons, our laser marking systems can be perfectly integrated into your workflow, whether it’s partially or fully automated.

PLC

Fully Programmable

Robotics, Hopper Loaders & Conveyers

Complex Machine Vision & Barcode Reading

Engineered Equipment Options for Your Application

Power 1064nm fiber lasers.

Our Standard Laser Marking Machines can be equipped with a 20W, 50W, or 100W fiber laser based on your marking requirements. However, an engineered system can go beyond these wattages based on your specific marking requirements.

5W & 10W

355 nm UV

IR / UV

Picosecond

IR / UV

Femtosecond

Other Wavelengths

Go beyond fiber.

Our sister company, DPSS Lasers specializes in ultraviolet and Ultra-Fast laser marking systems. With high peak powers, consistent repetition rates, and low thermal damage, UV and Ultra-Fast lasers are ideal for marking and engraving difficult materials, including ceramics, plastics, and metals.

5W & 10W

355 nm UV

IR / UV

Picosecond

IR / UV

Femtosecond

Other Wavelengths

Articulated robotic arms.

The programmable PLC in our laser marking systems allows you to add partial or fully automated solutions, including robotic arms for assembly and part loading.

Conveyers and belts.

Conveyors and belts integrate seamlessly with our laser marking machines to streamline material handling, speed up production, and boost throughput. They eliminate manual loading for Fiber/IR parts and enable UV and Ultra-Fast lasers to “mark on the fly.”

Automated infeed systems or hopper loaders.

By automating the loading process, Hopper Loaders eliminate manual intervention and ensure a steady flow of parts with the push of a button, allowing your laser systems to operate at peak efficiency.

Application specific vision systems.

Our engineers can design vision systems for specific part marking requirements, including the most advanced projects.

Read and grade complex barcodes with ease.

After laser marking is complete, barcode scanners verify their functionality and quality, including the most complex and small codes.

Advanced, application specific solutions.

Our engineers can create fully custom work holding systems and rotaries, tailored to your application requirements. That includes solutions for the most complex pieces.

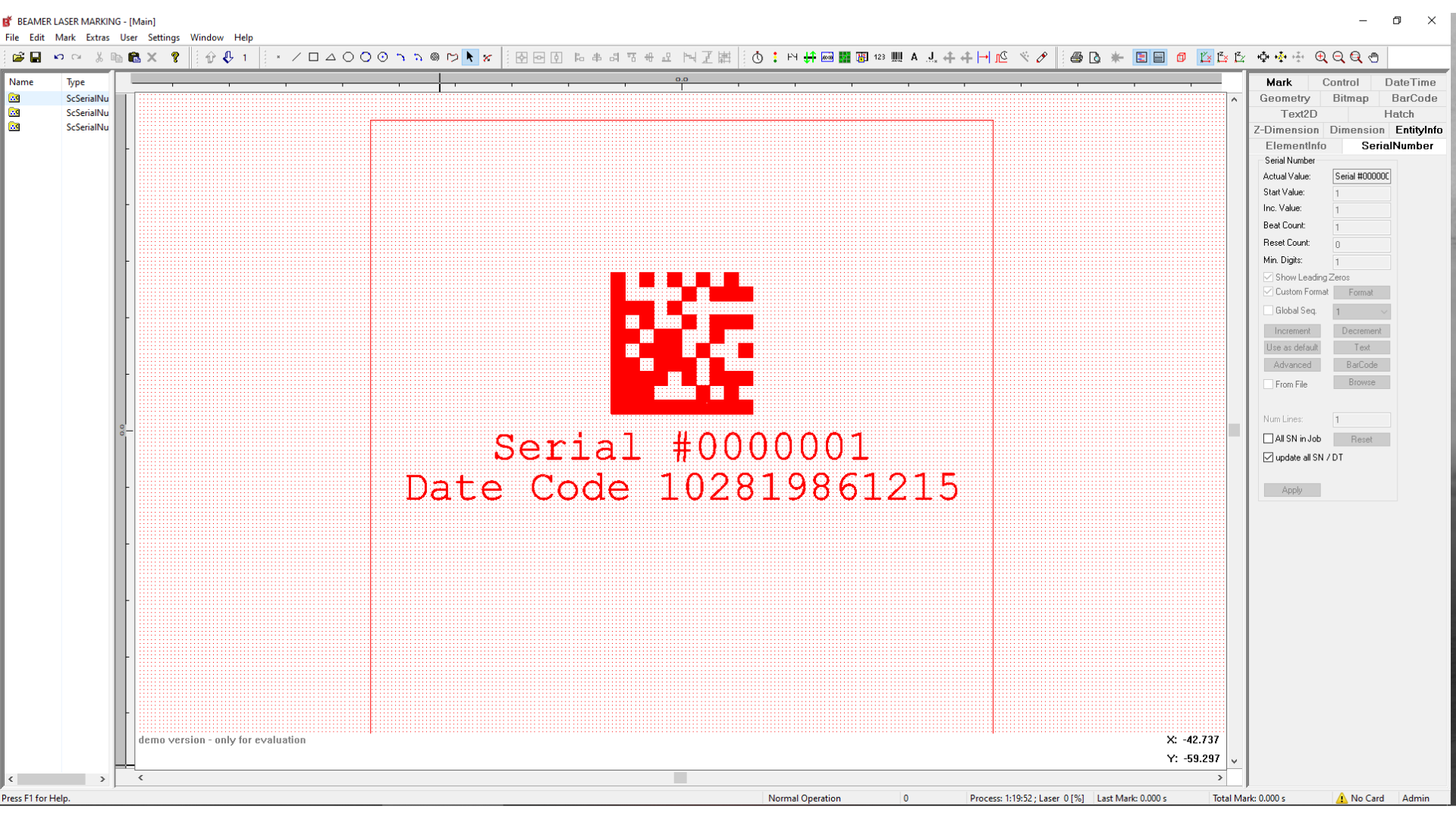

Connect to existing business systems.

Our “hand shake” software allows Marking Creator 3.0 to “talk to” critical business systems, including ERPs, serial number managers, and other machine equipment that imports data for marking. r