Laser Marking

NO MATTER THE INDUSTRY

From Medical to Defense, We Can Achieve Every Mark

FOR EVERY APPLICATION

Different Marks for Application-Specific Tasks

EASY TO ACHIEVE

User-Friendly Machines & Software

Laser Marking Vs. Etching

Fiber laser marking systems can laser etch a variety of materials, including metals, plastics, and ceramics. Contrast marking involves creating a permanent discoloration on the material, producing either lighter or darker marks on the substrate.

Easy to Edit

Failsafe Settings

Oxidation

Oxidation microscopically raises the surface of a metallic material and oxidizes its top layer, creating a dark, often black, mark. This method is particularly effective on ferrous materials.

Annealing

Annealing ferrous metals creates a corrosion-resistant black mark below the material surface. And depending on the carbon content of substrate, the mark will not disturb the outermost layer or affect its anti-corrosive properties.

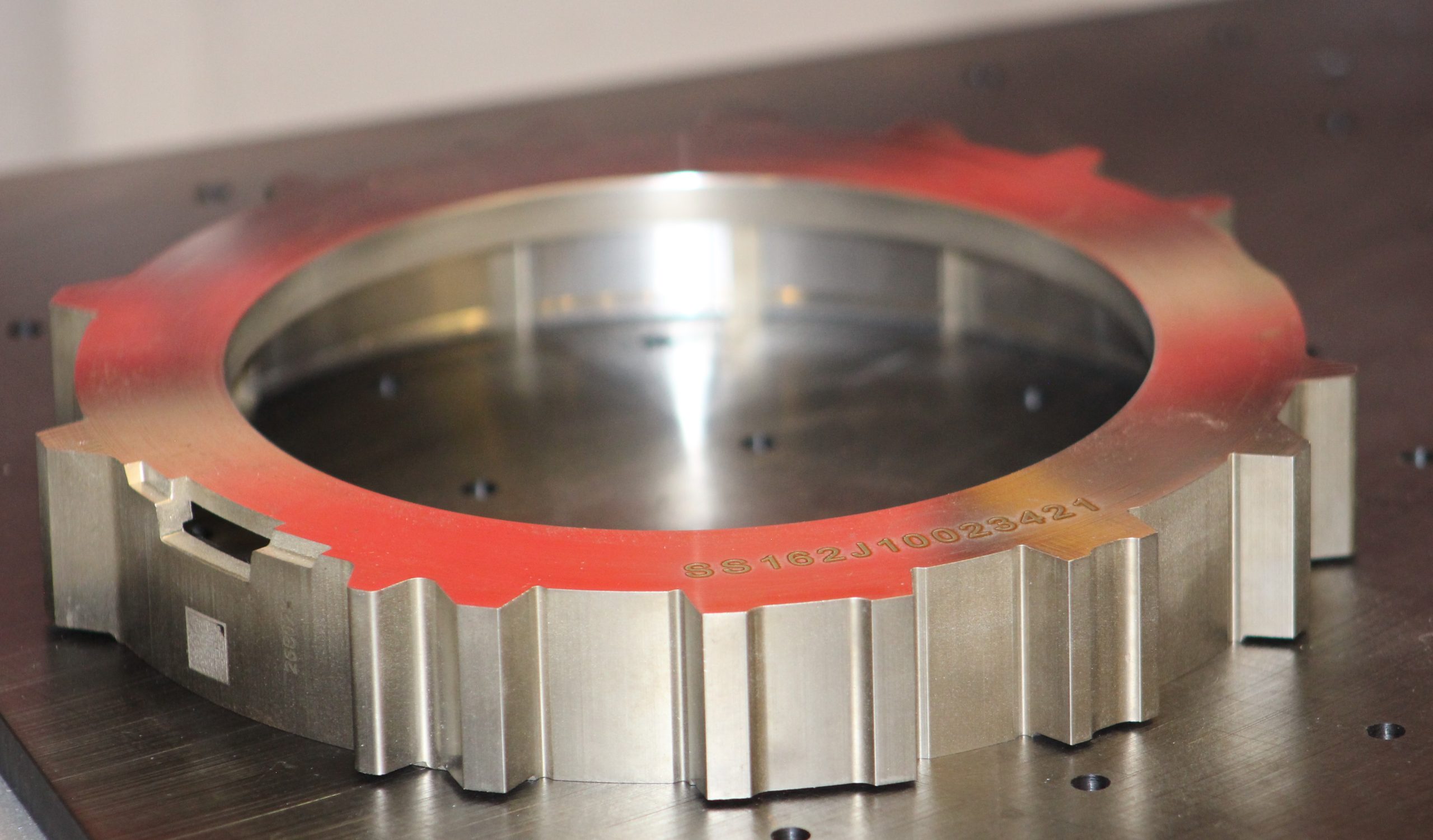

Deep Engraving

Deep engraving is the process of rapidly ablating the top layer of a metallic surface through multiple repetitions. This process is ideal for industries like firearms, aerospace, and defense, where deep, clear markings are essential. Using the right wattage, such as 50W or 100W systems, ensures efficiency and meets depth specifications on metals like steel, aluminum, and Inconel.

Etching

Etching with a 1064nm fiber laser

is a fast marking method used

in various applications, often

alongside oxidized marks.

Foaming

Using a marking process that

precise and permanent microscopic

bubbles, foaming creates a light

mark on dark materials, including

plastics, polymers, and resins.

Charring

Using a marking process that precise

and permanent microscopic bubbles,

charring creates a dark mark on

light materials, including plastics,

polymers, and resins.