Medical

At Beamer Laser Marking Systems, we understand the critical nature of precision and compliance in the medical device industry. That’s why we offer a comprehensive range of laser marking solutions designed to meet the most stringent standards.

Laser marking in the medical manufacturing industry.

Exceed Regulatory Demands

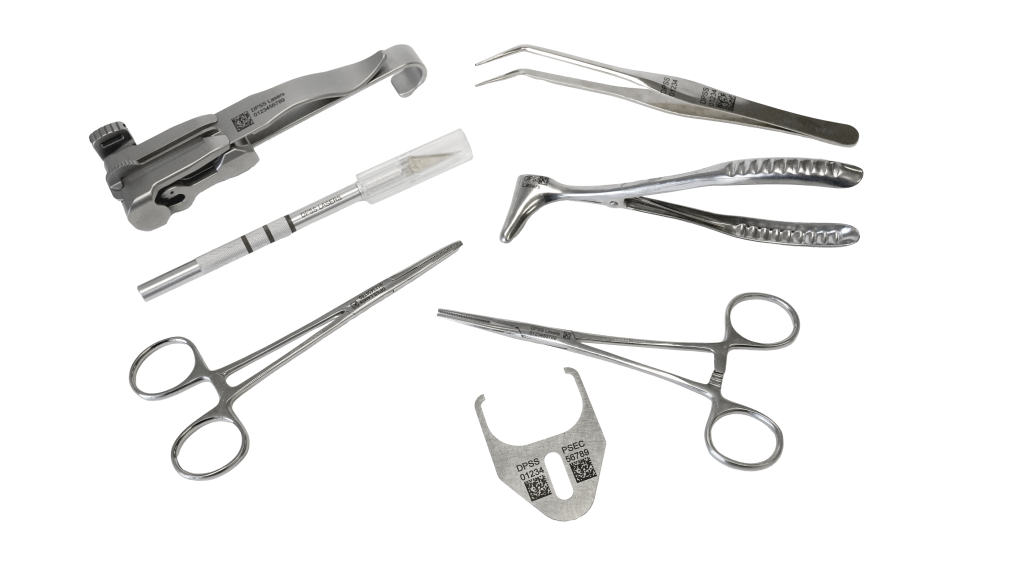

The FDA mandates clear and consistent marking of medical devices through the Unique Device Identification (UDI) system. UDIs facilitate comprehensive tracking throughout a device’s journey, from manufacturing to patient use. This fosters patient safety, streamlines post-market surveillance, and drives innovation within the medical device industry. Laser marking is the ideal solution for this standard due to its efficiency, accuracy, and permanency, all while maintaining the integrity of your devices.

UDI Numbers

Serial Numbers

Part Numbers

2D Codes

Create Permanent, Legible Marks

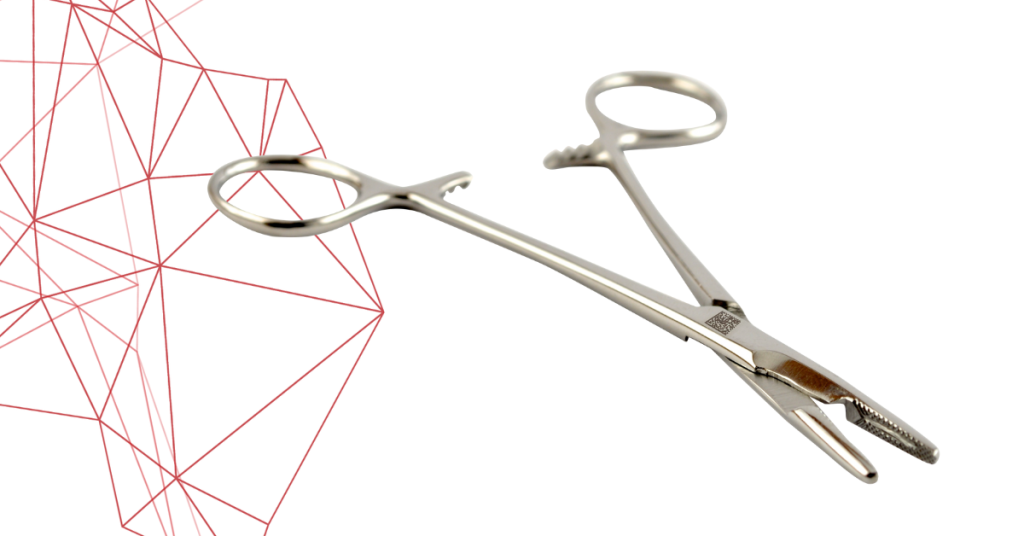

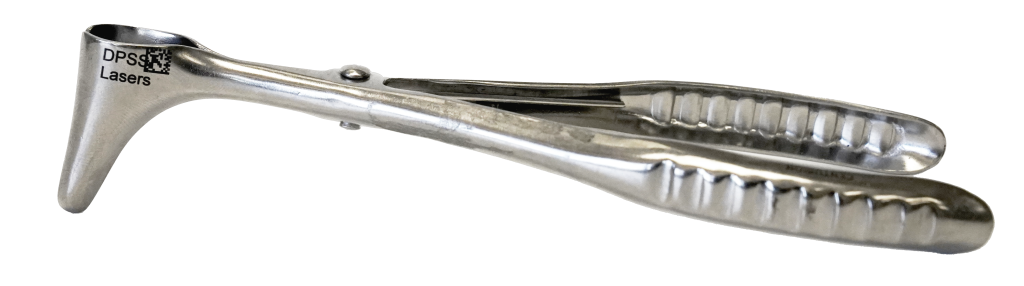

Unlike traditional methods, laser marking delivers permanent, corrosion-resistant etchings on your medical devices. This precise, non-contact process ensures vital information remains clear throughout a device’s lifecycle, even after sterilization and rigorous use. The laser marking process preserves the integrity of your materials, including stainless steel, titanium, and biocompatible polymers, allowing them to withstand demanding environments and stringent testing without compromising performance.

Eliminate Costs & Streamline Processes on Many Materials

Beamer Laser Marking Systems isn’t just about creating clear and compliant markings on your medical devices; it’s about streamlining your entire production process. Compared to traditional marking methods, laser marking eliminates the need for consumable inks or replacement parts, reducing ongoing costs. Furthermore, the speed and precision of laser marking allows for faster integration into your production line, minimizing downtime and maximizing throughput. This efficient, single-step process eliminates the need for multiple marking stages, saving you valuable time and resources. By investing in Beamer’s laser marking technology, you can achieve significant cost savings and experience a smoother, more efficient production flow.

REDUCE COSTS

No associated consumable costs

SUBSTRATES

Mark metals, composites & exotics

Picosecond IR Lasers

Partnered with our sister company, DPSS Lasers, these medical devices were marked with a Picosecond IR Laser. Our Picosecond IR Lasers are the premier choice for marking medical devices due to their ability to create ultra-dark, ultra-fast marks on the most reflective of metals.

Industrial Grade Solutions

Beamer Laser Marking Systems provides medical device manufacturers with marking solutions that increase productivity, efficiency, and meet or exceed regulatory requirements. And with an unmatched 100,000+ hour lifespan, our American-made, industrial grade fiber lasers provide consistent performance over extended periods of use, and reduced downtime and maintenance costs.

100,000+

Hour Lifespan Reduces Downtime and Maintenance Cost

CONSTRUCTION

1″ Steel Tube Frame and Powder Coated Steel Panels