T-Series Laser Marking Machine

OPENING

Turntable

11″ MAX

Part Height

AXES

Z-Axis

Your gateway to automation.

The T-Series machine was designed for high-volume marking. Simply place parts to be marked on the rotating table, open the Marking Creator 3.0 program that will run, press the “Start” button, and watch the table turn. As parts are being marked, finished items from the other side of the table can be unloaded and reloaded for the next cycle, resulting in increased throughput and reduced cycle times.

Equipped with auto door from the start.

The T-Series Laser Marking System includes a fully automated turntable door.

GATEWAY TO

Automation

Button & Cycle Start

Industrial-grade construction.

The T-Series Laser Marking Machine frame is constructed using industrial grade, 1″ square steel tubing, welded and powder coated by fabricators at our Flushing, Michigan facility. Its exoskeleton consists of 1/4″ plated steel panels, including the fast, smooth turntable door with work safe window. The T-Series is controlled with Marking Creator 3.0 software installed on a monitor that rests on a double-jointed, swinging arm. It also has industrial-grade casters for portability around any facility.

FRAME

1″ Square Steel Tube

DOOR

Fast Rotating Turntable with Work Safe Window

DASHBOARD

Moveable Arm with Monitor & Controls

Standard Equipment Options for Your Application

Powerful 1064nm fiber laser options.

The T-Series Laser Marking Machine can be equipped with a 20W, 50W, or 100W fiber laser based on your marking requirements.

20W

Fiber/IR

50W

Fiber / IR

100W

Fiber / IR

Variable Pulse

Go beyond fiber.

Our sister company, DPSS Lasers specializes in ultraviolet and Ultra-Fast laser marking systems. With high peak powers, consistent repetition rates, and low thermal damage, UV and Ultra-Fast lasers are ideal for marking and engraving difficult materials, including ceramics, plastics, and metals.

5W & 10W

355 nm UV

IR / UV

Picosecond

IR / UV

Femtosecond

Other Wavelengths

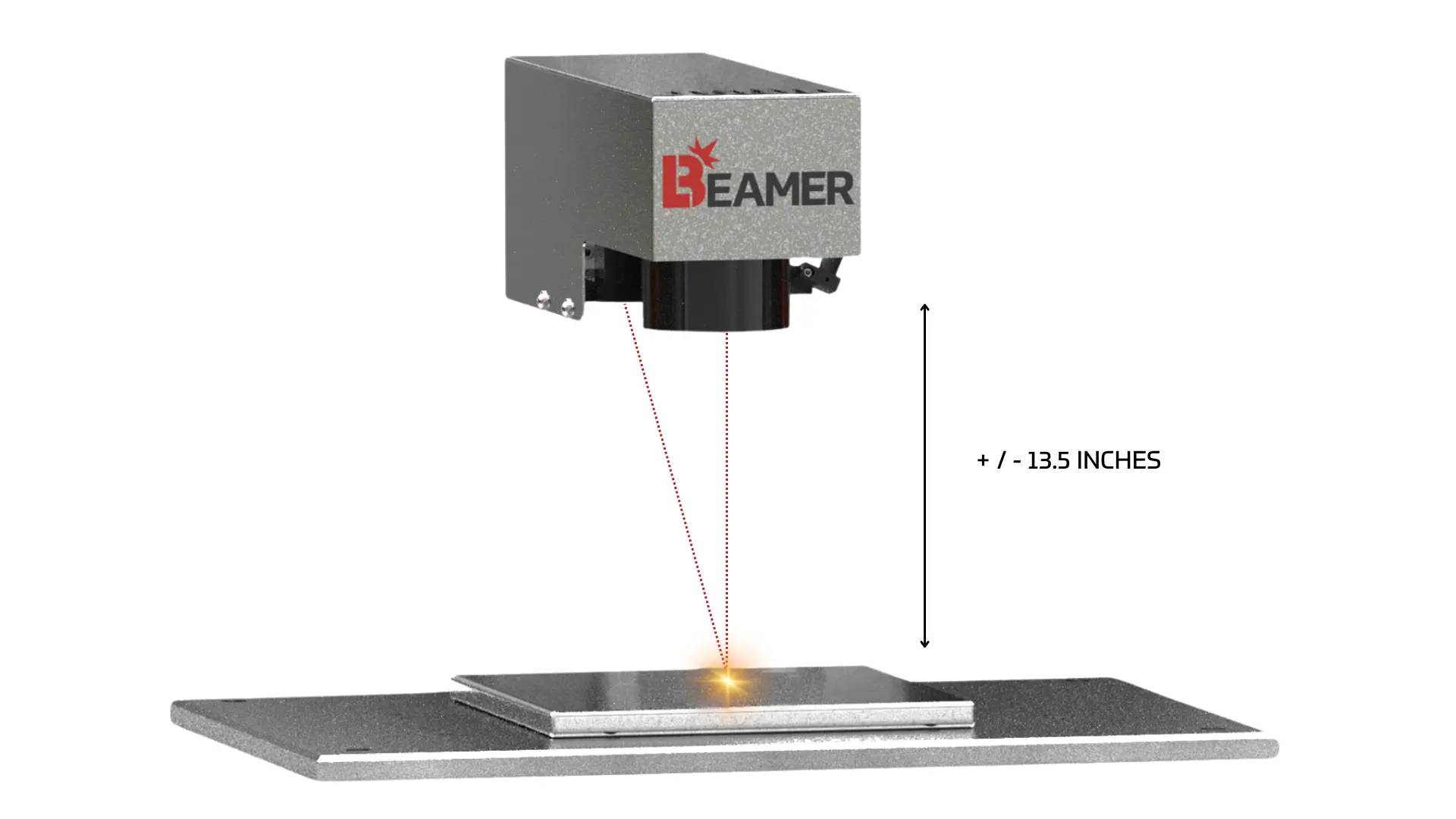

Speed through part setup by adding auto focus to your build.

Auto Focus allows users to accurately adjust scan head height up to 13.5 inches with the push of a button, eliminating the need for manual adjustments and accelerating new part setup.

10X

Faster Setup

+/- 13.5 inches

3-tiered, stacked filtration for particulate elimination.

Through extensive testing and case studies, our partnership with TBH has identified the optimal fume extraction pairings for each of our standard systems. With simple filter replacement and powerful control electronics, the LN260 Fume Extraction Unit ensures industrial safety and health protection when added to your T-Series Laser Marking System.

SAFETY

Protection for Worker Lungs

& Respiratory Tracts

DOWNTIME

Maximize Laser Life &

Minimize Machine Maintenance

Simplify part alignment with a Vision System.

Add a Vision Systems to provide the operator a real-time preview of your part and marking entity.

BASIC

Mark & Part Alignment

ADVANCED

Barcode Reading

& Grading

PRO

Recognition, Rotation & Orientation

Automation ready from the start.

Regardless of the configuration of your machine equipment upon initial purchase, it is automation ready and completely expandable via a fully programmable PLC.

PLC

Fully Programmable

Robotics, Hopper Loaders & Conveyers

Complex Machine Vision & Barcode Reading

Easy to Use Software

The computer mounted via swinging arm on the B-Series is preloaded with our graphical process-oriented software, Marking Creator 3.0. The Marking Creator interface allows users to precisely control laser parameters, build automation scripts, and edit images and text artwork with ease.

PENS

18 Preset & 255+ Customizable

UOM

Quickly change between metric & imperial

True Type Fonts

Sample Testing